The Electrode Code

Reward

Not specified

Deadline

February 6, 2026

Time remaining

Organizer

Emerson

Host Organization

Challenge Description

ActiveLanguage: English

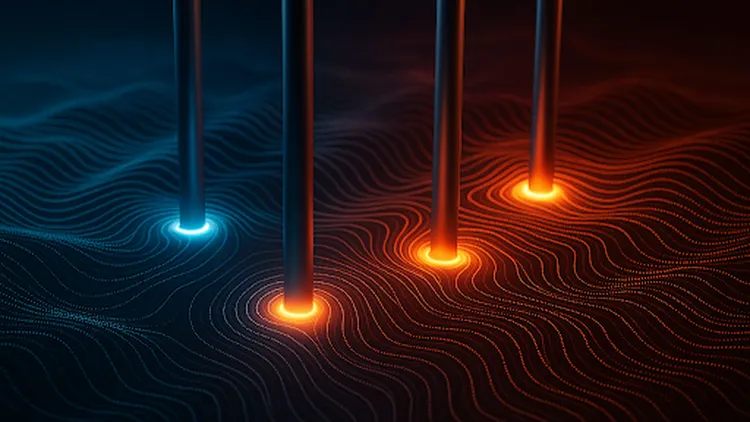

Across industries that move the world’s most critical fluids. From oil and gas to chemical manufacturing and water treatment, precision flow measurement keeps operations efficient, sustainable, and safe. Among the technologies that make this possible, electromagnetic flowmeters (magmeters) stand out for their unmatched reliability and accuracy. They measure flow without obstruction, using electromagnetic fields to turn the movement of a fluid into precise, real-time data. But even the most proven technology faces limits when exposed to the complex chemistry of real-world process conditions.For decades, Emerson has led the advancement of flow and process measurement, developing the industry’s most trusted magmeters under its Rosemount™ brand. Now, Emerson is turning outward, inviting engineers, scientists, and innovators to help solve the next challenge in this field: electrode coating buildup. Substances like paraffin, scale, and abrasive particulates can accumulate on electrodes, distorting flow readings and forcing operators into costly maintenance cycles and unexpected shutdowns.The Electrode Code seeks innovative solutions that keep magmeter electrodes clean, accurate, and dependable for longer. Success means extending the meter’s effective lifespan, reducing cleaning frequency, and maintaining the precision that industries rely on, even in the harshest environments.Winning solvers will share in a $30,000 prize pool and may earn the opportunity to collaborate directly with Emerson’s global R&D and manufacturing teams to bring their ideas from concept to commercial reality. By addressing this challenge, you’ll help shape the next generation of flow measurement , one that keeps industry moving without pause.

Description Length: 1739 charactersLast Updated: 12/15/2025

挑戰詳情

- 語言

- English

- 狀態

- 進行中

- 組織者

- Emerson

- 地點

- Global

- 難度等級

- medium

- 創建時間

- November 4, 2025 at 06:00 PM

Share Challenge

💡 Tip: Click "Go to Challenge Page" to open the original challenge page in a new window